Truspacer--Trusted brand of sealing spacer

Why is Truspacer trustworthy?

Our company's products are produced with high-quality raw materials, with a high-level R & D team as technical support, the company is equipped with professional testing personnel and equipment to test raw materials and finished products, each batch of finished products need to be strictly inspected to ensure that product quality meets the requirements of the national standard.

How high is the efficiency value of Truspacer spacer in actual operation? How much is the difference between the use cost and the vertical glue?

The use of aluminum strip gluing method to make insulating glass, in the case of 8-12 people, 8 hours of work, can produce 250-300 square meters. The use of Truspacer warm edge spacers to make insulating glass, in the case of 4-6 people, 8 hours of work, can produce 400-450 square meters. The process of Truspacer spacer is simple, the production efficiency is high, and the overall cost is lower.

Use Truspacer warm edge spacer to make insulating glass, do you still need supporting equipment?

Also need hot press machine and cleaning machine, our company also sells high-quality insulating glass production equipment, welcome to contact us to purchase.

Can the air tightness of Truspacer warm edge spacer meet the standard? How about the quality?

Truspacer warm edge spacer conforms to GB/T11944-2012 standard and has good air tightness.

Can the dew point test of insulating glass made of Truspacer warm edge spacer reach the standard?

In the case of strictly operating in accordance with our operating procedures, the dew point of the insulating glass of Truspacer warm edge spacer can reach -40℃, which can meet the requirement of the national standard.

What kind of desiccant is used in Truspacer warm edge sealing spacer? What are the special properties of this form of desiccant?

The desiccant used in Truspacer warm edge spacer is 3A molecular sieve powder.

The composition of normal air is: nitrogen accounts for 78%, oxygen accounts for 21%, and the rest is carbon dioxide, water, rare gases and impurities. 3A molecular sieve is characterized by only adsorbing moisture without absorbing other gases, the pore size of 3A molecular sieve is 3Å, while the diameter of water molecules is 2.68 Å, and the diameter of other gases in the air is greater than 3Å, so 3A molecular sieve can only adsorb water. If a 4A molecular sieve is used, the gas in the cavity will be adsorbed, and excessive suction will cause the insulating glass seal to fail.

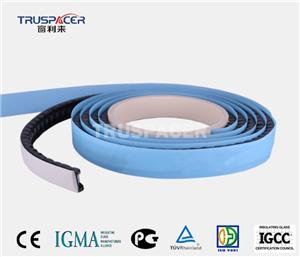

What is the warm edge spacer? What is the difference between warm edge spacer insulating glass and traditional trough aluminum insulating glass production process?

(1) Any kind of insulating glass spacer can be called a warm edge as long as its thermal conductivity is lower than that of aluminum metal. Warm edges can be obtained by three methods:

1.Non-metallic materials, such as super spacers, TPS, fiberglass strips;

2.Some metal materials, such as broken bridge spacers, composite rubber strips;

3.Metal spacers with lower conductivity than aluminum metal, such as stainless steel spacers.

(2) Process comparison:

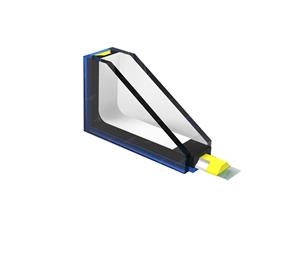

1. Structural characteristics gusseted angle of grooved aluminum insulating glass is a weak link, and the butyl glue is interrupted at the interslate. The corners of Truspcaer warm edge spacer are continuous, so Truspacer warm edge spacer can greatly reduce the water vapor permeability.

2. Tightness the bonding width of grooved aluminum insulating glass butyl sealant is only 5mm, while the sealing bonding width of Truspacer warm edge insulating glass is 8mm, so that the water vapor permeability is lower.

3. Energy saving the thermal conductivity of Truspacer warm edge insulating glass is lower than that of slot aluminum insulating glass, thereby reducing the heat conduction of the edge of the insulating glass.

4. Work efficiency only one product of rubber strip can replace several products such as butyl sealant, aluminum strip, gusseted angle and desiccant, saving process and labor, and higher production efficiency.