Horizontal Insulating Glass Hollow Glass Machine Production Line

The introduction of function to Horizontal Insulating Glass Hollow Glass Machine Production Line

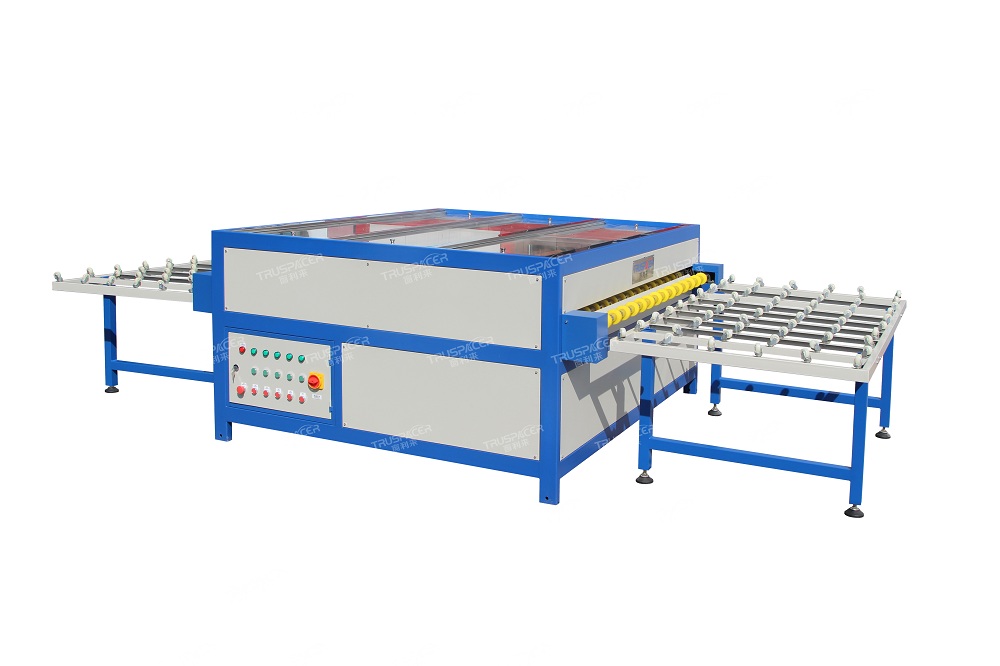

Washing and drying machine,before making IG, the glass must be cleaned.

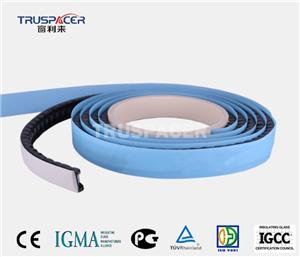

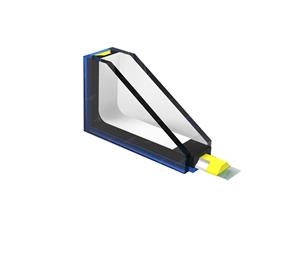

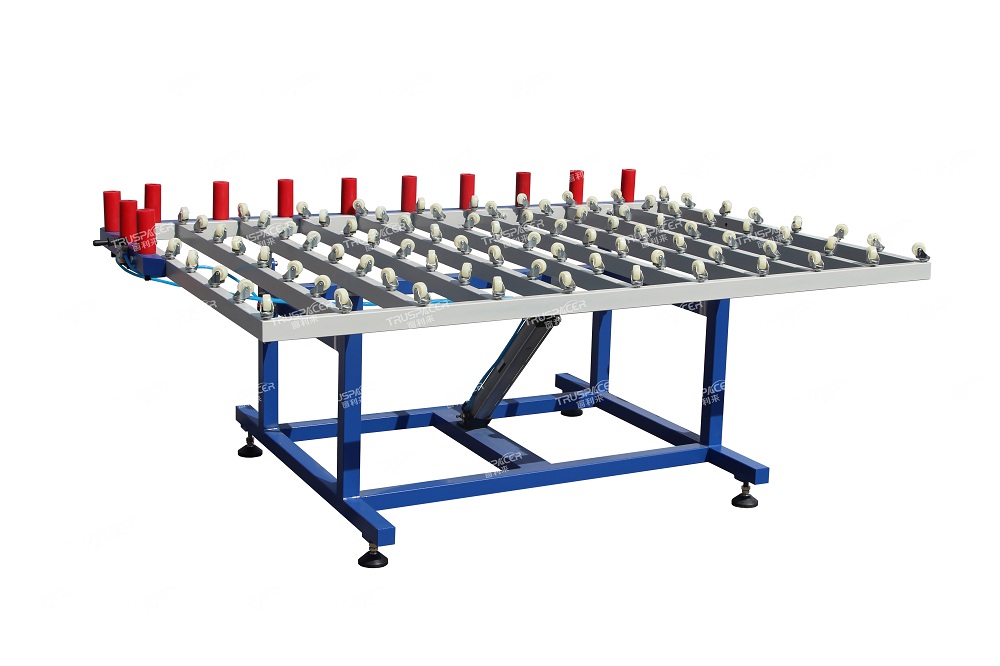

Air folating assembly station,when inhaling, the glass is fixed on the table, apply butyl spacer straight and efficiently. When blowing, the glass is suspended on the table, rotate and move without scratching the glass surface.

Rolling-over table,nylon retaining posts form a right angle,ensure that the glass is stable and the glass are accurately combined.

Hot press machine,the laminated insulating glass must be heated and pressed at high temperature,ensure that the butyl sealant on both sides of the spacer is fully bonded to the glass.

Panjin Truspacer Insulating Glass Material Co., Ltd adhering to the principle of high quality, integrity, pragmatic and innovative, the company mainly produces single seal flexible warm edge IG spacer, single seal rigid IG aluminum spacer, dual seal rigid warm edge IG sealing spacer, insulated glass sealant and molecular sieve, sealing spacer for fireproof or waterproof, horizontal insulating glass equipment and so on.

A basic IG production line costs only one hundred thousand yuan, 4 people, about 400-600 pieces of IG per 8 hours,and the overall footprint is small,single line layout covers 28 square meters, choose Truspacer IG production line, it will help you save more and earn more!