Truspacer sealing spacer aging resistance test

Truspacer sealing spacer aging resistance test

In order to test the aging resistance of the window insulating glass warm edge spacer and compare it with other manufacturers' spacers, prepare a strip sample, and after irradiating the ultraviolet lamp for 168h, the sample is removed, observed and compared.

Spacer samples that have not been irradiated by ultraviolet rays.

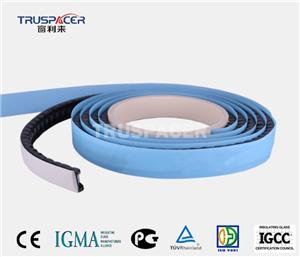

Sealing spacer samples irradiated with ultraviolet light for 168 hours.

Enlarged view of the aging details of other manufacturers' sealing spacers.

Comparison of aging resistance of Truspacer spacers with other manufacturers (after 168h of UV irradiation)

projectproducts | Truspacer | Other manufacturers |

Surface State | No noticeable change | cracking,blistering, severe aging |

Adhesive | No noticeable change | worse |

Flexibility | No noticeable change | worse |

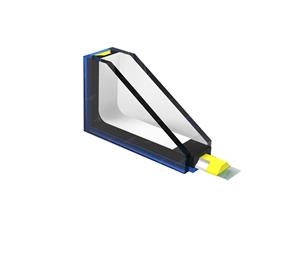

The poor UV resistance of the sealing spacers means that the aging resistance of the adhesive bead is poor, and the production of insulating glass with such sealing spacers will not only cause chemicals to be generated inside the insulating glass but also lead to poor adhesive between the sealing spacers and the glass, resulting in the failure of the insulating glass seal, see the chart below.

Volatiles are generated inside the insulating glass.

Insulating glass seal failure.

Through the above test comparison, it is found that the aging resistance of Truspacer warm edge spacer is excellent, and the quality is significantly better than that of other rubber strips. Such excellent quality mainly depends on the scientific ratio of raw materials, the selection of high-quality raw materials and exquisite production technology, the raw materials used in our rubber strip products are high-quality high-grade raw materials produced by well-known manufacturers, and resolutely refuse recycled materials. The ratio of raw materials, with modern production technology and strict quality inspection procedures, is meticulous to create ingenious quality.