Reveal the price difference of insulating glass warm edge rubber strip

Reveal the price difference of insulating glass warm edge rubber strip

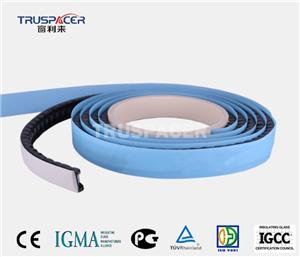

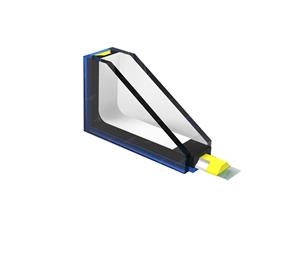

Truspacer is a warm edge spacer system ideal for high-volume production of insulating glass, it contains butyl sealant, 3A molecular sieve, undulating aluminum spacer bar and heat insulation strip and so on, it can replace the traditional aluminum bar and help to improve the insulating glass production efficiency, no need the secondary seal.

No.1 Butyl Rubber

Butyl rubber, which has excellent air tightness, mainly plays a water vapor sealing role in the rubber strip, and is divided into two categories: high-quality butyl rubber and recycled butyl rubber. Among them, high-quality butyl rubber has excellent air tightness, good chemical resistance and corrosion resistance; Individual manufactures in order to reduce the cost will usually choose recycled butyl rubber, recycled butyl rubber is generally the tire inner tube recycling redone products, odor, poor sealing, poor formula stability, the price is 40% of high-quality butyl rubber, because it is recycled and redone products so the performance is not good, and the sealing performance can not be fully guaranteed.

No.2 Polyisobutylene

Polyisobutylene, divided into high molecular weight polyisobutylene and low molecular weight polyisobutylene, in which high molecular weight polyisobutylene has viscosity and high strength; Low molecular weight polyisobutylene has poor viscosity, low strength, and its produces are prone to deformation, and the price is one-third of high molecular weight polyisobutylene. Adding a reasonable proportion of high-quality polyisobutylene can ensure the long service life of the rubber strip, otherwise the service life of the products is greatly reduced.

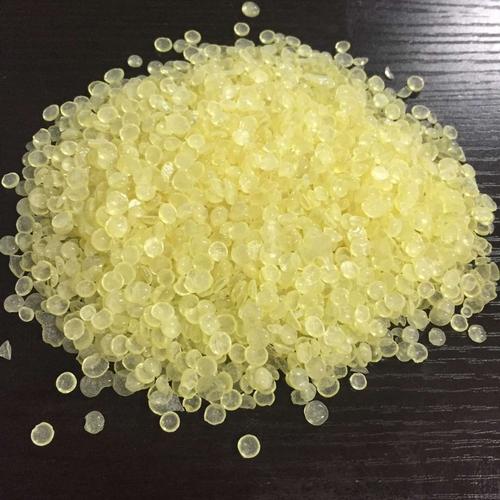

No.3 Petroleum Resin

Petroleum resin, divided into C5 hydrocarbon resin and C9 hydrocarbon resin. C5 petroleum resin has good viscosity, anti-aging, less odor, less volatiles, and more environmental protection; C9 petroleum resin has a large odor, poor anti-aging performance, and the price is less than one-third of C5 petroleum resin. The quality and amount of resin added determine the viscosity and cohesive strength of the adhesive strip, thereby ensuring the cold flow of the adhesive strip at room temperature.

No.4 Molecular Sieve

Molecular sieve, divided into 3A molecular sieve and 4A molecular sieve, 3A molecular sieve only absorbs water, individual manufacturers in order to save costs will reduce the amount of molecular sieve added to one-third of the normal amount or even less, insufficient addition of molecular sieve will lead to unqualified insulating glass dew point; Or choose 4A molecular sieve with half the price of 3A molecular sieve, 4A molecular sieve in addition to absorbing water will also absorb nitrogen and oxygen in the insulating glass cavity, such as excessive absorption will cause insulating glass deformation and seal failure. Truspacer has its own molecular sieve firing furnace, which can ensure product quality from the source.

No.5 Carbon Black

Carbon black, Truspacer spacer is made of high-quality furnace carbon black as raw material, which has good stability and high strength; Small factories use recycled cracked carbon black with many impurities, poor reinforcement, not easy to disperse, and the price is only half of high-quality carbon black. The quality of carbon black directly affects the supporting performance and anti-aging ability of the rubber strip.