Insulating glass spacer system automatic production line

Company profile

Panjin Truspacer insulating Glass Material Co.Ltd. Was founded in 1996, located in the wetland city of Panjin, Liaoning Province. The company covers an area of 20000 square meters and has more than 100 employees. It is an enterprise engaged in the research, development, production and sales of insulating glass sealing material systems.

After more than 20 years of development, the company’s main product is insulating glass sealing spacer, which has been sold in major cities across the country and exported to more than 60 countries and regions around the world, such as the United States, Germany, Britain, France, Japan, etc. The product quality has been recognized by customers.

As a member of the China Building Glass and Industrial Glass Association and the Door and Window Committee of the China Building Metal Structure Association, Truspacer pays special attention to the technical innovation of its products. The company has a number of utility model patents. Its products have passed the American IGCC certification, the European CE certification, the National Building Materials Testing Center, the Qinhuangdao National Glass Quality Inspection Center and other department’s tests, as well as the ISO9001 quality system certification. Truspacer takes quality as the core, research and development as the driving force, constantly upgrades products, and strives to provide customers with the whole industry chain services. The company spirit of “quality integrity, pragmatic innovation” purpose, do not forget the original intention, forge ahead, but also look forward to mutual benefit with friends from all walks of files, common development!

Process display

Multiple store tanks can be automatically replaced

Fully automatic PLC control

Innovative V-notch design

Automatic filling desiccant

Butyl coating automatically

The back of the aluminum spacer is continuous without break point after bending

New technology independently developed by China

Qualification certification

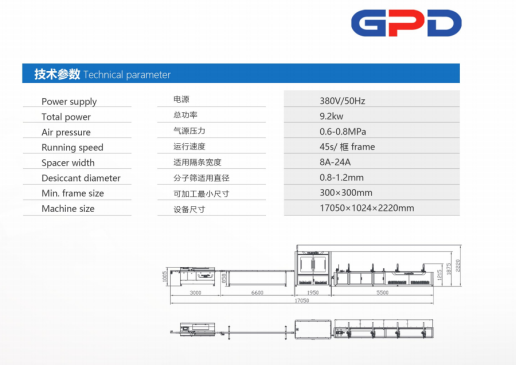

INSULATING GLASS SPACER SYSTEM AUTOMATIC PRODUCTION LINE

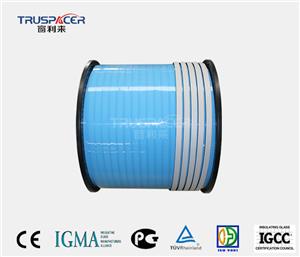

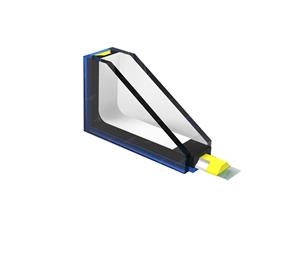

The production line adopts innovation insulating glass spacer system manufacturing technology and process, which mainly consists of material rack, machining center, conveying belt and butyl coating machine. It can process 8A-24A aluminum spacer with frame size of 300-2000mm. Automatic feeding, automatic filling, automatic gluing, automatic frame making, to achieve the full automatic production of aluminum frame, which is a new model of making insulating glass frame.

Advantures:

1.Save labor costs: Insulating glass traditional frame process needs 3-4 people. GPD automatic production line only needs 1-2 people.

2.Productivity improvement: Intelligent control system, no need for manual intervention. Improve efficiency and achieve high return on investment.

3.Qualified rate: Intelligent computing processing for precise and efficient production eliminating human error.

Technical features:

1.Fully automatic PLC control, touch screen operation.

2.Intelligent calculation of materials, no manual.

3.The material rack can automatically change various specifications of spacer.

4.Innovation V-notch design, continuous back without breakpoint after bending.

5.From the loading spacer to the end of the spacer coating, no manual.

6.The machine can process aluminum spacer and warm edge spacer.