Advantages Of Using Hollow Glass Aluminum Spacers On Insulating Glass

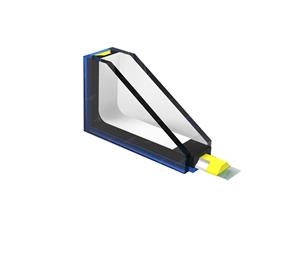

1.Ordinary aluminum strips use four joint angles to make hollow glass. The hollow corners of the hollow glass are poor in sealing effect, easy to leak and permeable, which can easily cause the failure of the insulating glass and shorten the service life of the insulating glass.

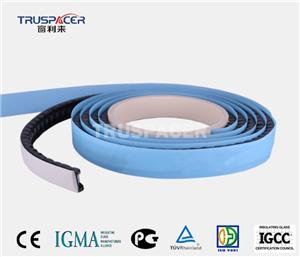

2. Insulating glass and aluminum spacers are made of continuous glass to make hollow glass. The hollow glass has no connecting parts at the four corners, and the sealing effect is excellent. It is not easy to leak, permeable, and prolong the service life of the insulating glass. At the same time, its performance and performance Both can compete with similar foreign products.

3. The density of the hollow glass aluminum spacer is smaller than that of the ordinary aluminum spacer. The standard density is 2.7g/cm, and the air permeability is very good. Although its material is soft, it is very rigid and will not appear for a long time. The deformation phenomenon greatly guarantees the stability of the insulating glass. The hollow glass aluminum spacer feels comfortable when touched by hand. It has a smooth and flat shape, looks like no impurities, and has a silvery white luster. It can maintain a smooth and translucent color no matter how long it is used, and it will not appear dull and dull. The hollow glass produced looks smooth and bright, and has strong anti-corrosion properties. Even in harsh environments, it will not be easily corroded. Rainwater washing will not cause corrosion and will always be good. Exterior. Greatly extend the service life of the insulating glass.

4. Hollow glass aluminum spacers have strong reflection ability, can effectively block the strong ultraviolet radiation, protect people's eyes and skin, the purer purity of aluminum strips, the better the reflective performance of the produced hollow glass. Insulating glass aluminum spacers also have strong low temperature resistance.